Tungsten Halogen Light Bulbs – History, Working, Construction and Applications

Tungsten Halogen Lamps – History, Working, Construction and Applications

| Tungsten Halogen Lamps |

| History of Tungsten Halogen Lamps |

| The original incandescent light bulb was invented by Thomas Edison in 1879. This bulb had a simple construction – a carbon filament inside a glass bulb with a vacuum. However, the carbon filament was inefficient and prone to early failure. This led to the development of tungsten filaments, which offered higher efficiency and longer life. The tungsten incandescent bulb was a big breakthrough and dominated lighting for decades. |

In 1959, General Electric introduced halogen gas into incandescent bulbs. This halogen gas reacted with the tungsten that evaporated from the filament during operation. This allowed the tungsten to be redeposited back onto the filament instead of simply condensing on the inner glass surface. This regeneration of the filament allowed it to last longer at higher temperatures, which increased efficiency. This was the birth of the tungsten-halogen lamp.

Over the following decades, incremental improvements were made in the gas fills, filament construction, and bulb shapes to optimize performance for different applications. Tungsten-halogen lamps continue to be designed and produced today as a high-quality light source option.

How Tungsten Halogen Lamps Work

The operation of a tungsten-halogen lamp is similar to a standard incandescent bulb. An electric current runs through a tungsten filament, causing it to glow white-hot and produce light. However, the halogen gas inside the bulb enables vital chemical processes that prolong the life of the filament:

As the filament heats up, some tungsten evaporates and absorbs into the nearby gas. The halogen gas reacts with the evaporated tungsten, forming tungsten halides. These tungsten halides readily diffuse back to the hot filament surface, decomposing and redepositing the tungsten back onto the filament.

This evaporation, transport, and redeposition cycle reconstructs the filament as it operates, countering damage from high-temperature operation. This regeneration enables the filament to last longer at higher temperatures and light outputs than a standard incandescent bulb.

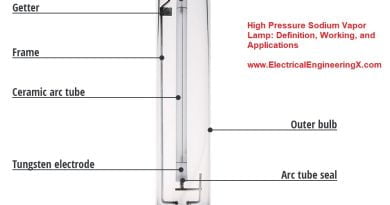

Construction and Components of Tungsten Halogen Lamps

While the halogen gas regeneration cycle is critical, tungsten-halogen lamps also rely on precision construction of other components for optimal performance:

Filament

- Made from tungsten for high-temperature resistance

- Coiled-coil or coiled-coil filament designs maximize light output

- Supported by fine wires called lead-in wires

Reflector

- Made from pressed glass with an aluminized coating

- The ellipsoidal shape directs light forward

Glass Envelope

- Made from fused quartz rather than standard glass

- Withstands higher bulb temperatures

Halogen Gas

- Usually, iodine or bromine combined with an inert gas

- Controls rate of halogen cycle reactions

Advantages of Tungsten Halogen Lamps

- High luminous efficacy – more lumens per watt than standard incandescent

- Excellent color rendering (CRI of 100)

- Long life – 2-4 times longer than traditional incandescent

- Small source size – focused beam with reflector

- Maintains lumen output over the life

Disadvantages of Tungsten Halogen Lamps

- Less efficient than fluorescent or LED

- Generates significant heat

- Requires adequate fixture ventilation

- Fragile filament and glass envelope

- Contains hazardous mercury (some types)

Applications of Tungsten Halogen Lamps

Some key applications that take advantage of tungsten halogen lamp properties:

- Stage lighting – compact source, beam control, CRI

- Film lighting – similar to natural light, CRI

- Portable work lights – focused beam, durability

- Auto headlights – small size, beam control

- Floodlighting – narrow beam over a distance

- Specialty projectors – high-intensity discharge

The Future of Tungsten Halogen Lamp Technology

LEDs as a Replacement

Over the past decade, LED lighting has taken over most lighting applications due to greater efficiency and longer life. LEDs now outperform tungsten halogen lamps in most ways while dropping in price. We will continue to see LEDs dominate the general illumination market. However, tungsten-halogen still has niche roles where its properties are preferred.

Improvements in Tungsten-Halogen Technology

Some ongoing research aims to further improve tungsten-halogen performance through:

- Alternate filament materials like tantalum to enable higher temperatures

- Use of xenon or krypton gases to reduce bulb heating

- Anti-reflective coatings on the envelope to minimize light loss

- Enhanced filament manufacturing techniques

While LEDs will continue to dominate, we can expect tungsten-halogen technology to remain valid for specialized applications, capitalizing on its unique advantages.

Tungsten Halogen Lamps vs. Incandescent Lamps

How do tungsten halogen lamps compare to traditional incandescent bulbs? We’ll break down the key differences, including efficiency, lifespan, and color rendering, to help you make informed lighting choices.

- Environmental Considerations

As we become increasingly conscious of our environmental footprint, examining the impact of lighting technologies is crucial. In this section, we’ll discuss the environmental aspects of tungsten halogen lamps, including disposal and energy efficiency.

- Maintenance and Safety Tips

To make the most of your tungsten halogen lamps, it’s essential to understand how to use and maintain them safely. We’ll provide practical tips to ensure both the longevity of your lights and your safety.

- Future Developments

The world of lighting technology is constantly evolving. We’ll glimpse ongoing research and potential advancements in tungsten halogen lamp technology, revealing what innovations may shape the future of lighting.

Conclusion

Tungsten-halogen lamps have played an essential role in the evolution of electric lighting, enabling more efficient incandescent bulbs since the 1960s. The ingenious use of halogen gas regeneration allowed the filament to operate at higher temperatures and last longer while maintaining the excellent color properties of incandescent lighting. While LEDs now outperform tungsten-halogen lamps for most lighting applications, the technology still fills certain niche roles and will likely continue improving through ongoing research and development. Tungsten halogen lamps have a rich history and a bright future. They have consistently provided us with reliable and efficient lighting solutions, making them a staple in various applications. Whether you’re lighting up a room, a stage, or a laboratory, these lamps continue to shine brightly.

Frequently Asked Questions (FAQs)

| Q: Who invented the tungsten halogen lamp? |

| A: General Electric engineers invented the first commercial tungsten halogen lamp in 1959. |

Q: How does a halogen lamp produce more light than a standard incandescent?

A: The halogen cycle allows the tungsten filament to operate at a higher temperature, producing more light output.|

Q: What is the typical lifetime of a halogen lamp?

A: Most halogen lamps last 2,000 to 4,000 hours, 2-4 times longer than a standard incandescent.

Q: What are the different types of tungsten halogen lamps?

A: Common varieties include tubular, reflector, capsule, and projector configurations.

Q: Why are halogen lamps not as efficient as LED lamps?

A: Halogen lamps produce light through incandescent heating, which is inherently less efficient than LEDs that produce light directly from electricity.

Q: What gas is used in halogen lamps?

A: Most use iodine or bromine combined with an inert gas like nitrogen or argon.

Q: Do halogen lamps contain mercury?

A: Some types contain a small amount of mercury, while others are mercury-free.

Q: What is the CRI of halogen lighting?

A: Halogens have a color rendering index of 100, meaning perfect color representation.

Q: Where are halogen lamps used?

A: Common uses include spotlights, headlights, projectors, photography lighting, and more.

Q: Are there any improvements being made to halogen technology?

A: Ongoing research aims to enhance performance using alternate filament materials, improved coatings, and different gases.

MCQs

1. Are tungsten halogen lamps the same as incandescent bulbs?

Tungsten halogen lamps are an improved version of incandescent bulbs, offering higher efficiency and longer lifespan.

2. What makes tungsten halogen lamps efficient?

Their efficiency is due to the halogen cycle, which regenerates the tungsten filament, allowing it to operate at higher temperatures.

3. Where are tungsten halogen lamps commonly used?

They are used in general lighting for homes and businesses and in specialized fields like microscopy and film production.

4. Are tungsten halogen lamps environmentally friendly?

While they are more efficient than traditional incandescent bulbs, they still require proper disposal and consideration of energy use.

5. How can I extend the lifespan of my tungsten halogen lamps?

Avoid touching the bulb with bare hands, as oils from your skin can cause premature failure. Also, use the lamp within its specified voltage range.

6. Are there LED alternatives to tungsten halogen lamps?

In recent years, LED technology has emerged as a highly efficient alternative to tungsten halogen lamps.

7. Can tungsten halogen lamps be dimmed?

Yes, many tungsten halogen lamps are dimmable, providing flexibility in lighting control.

8. Do tungsten halogen lamps produce UV radiation?

Tungsten halogen lamps emit some UV radiation, but it is typically minimal and can be reduced with proper lamp coatings.

9. How do I properly dispose of tungsten halogen lamps?

It’s best to follow local regulations for lamp disposal, which often involve recycling to minimize environmental impact.

How do I copyright the content on my web site?